FOR OWNERS AND EPC CONTRACTORS

Minimize delays and cost overruns on oil + gas projects with ALICE

Owners, contractors, and consultants use ALICE from the early stages of an and oil and gas project -- including pre-FEED and FEED -- all the way to commissioning and shutdown on various oil + gas projects.

ALICE is purpose-built for capital engineering and construction projects, such as processing plants, refineries, storage terminals, pipelines, and more.

Submit bids with confidence

Use ALICE to explore a variety of construction options and create detailed, resource-loaded schedules you need to pursue and win profitable projects.

Optimize scheduling with AI

Optioneer execution strategies in ALICE to identify the cost and time impact of your business resource decisions, for example:

"What if I increase my remote site's bed capacity by 45?"

Generative risk mitigation

ALICE allows for rapid modeling and simulation of various risk scenarios to determine their impact on the schedule and develop robust contingency plans.

WHITEPAPER

Optimizing the construction of oil and gas facilities with generative construction technology

This whitepaper explores the use of generative construction technology in the design, planning and construction of oil and gas facilities.

This transformative approach harnesses the power of advanced algorithms and computational capabilities to generate design solutions that are not just efficient but also optimized to meet the intricate demands of oil and gas infrastructure.

“The savings of both time and money that we've identified with this initial work on SCS East has been significant, and we're now looking forward to expanding our use of ALICE to other portions of the project.”

ALICE PRICING

Tell us about your project needs and we’ll follow up with a consultation call to discuss how ALICE can drive results and share tailored pricing →

What type of company do you work for?

What is the size of your project?

What are your top priorities?

Which of the following best describes your business model?

What are your top priorities?

What is the construction value of your average project?

We need a bit more information to prepare your custom quote

Almost done! How should we reach out to you?

Tell us more about yourself.

Thanks!

We’ll review the information you submitted and be in touch shortly. In the meantime, check out some of these links if you want to learn more about us.

ALICE works with the world's leading contractors to solve their most pressing construction challenges with oil and gas construction software.

Optimize every construction phase with ALICE

ALICE gives you new planning and construction super powers

Oil & Gas Construction Management Software

More resources from ALICE

Overview: ALICE for oil and gas plant construction

Read how you can optimize your oil and gas construction project and build faster with ALICE.

Webinar: Generative AI meets construction

In this webinar, we answer the million-dollar question: can generative AI be applied to construction workflows?

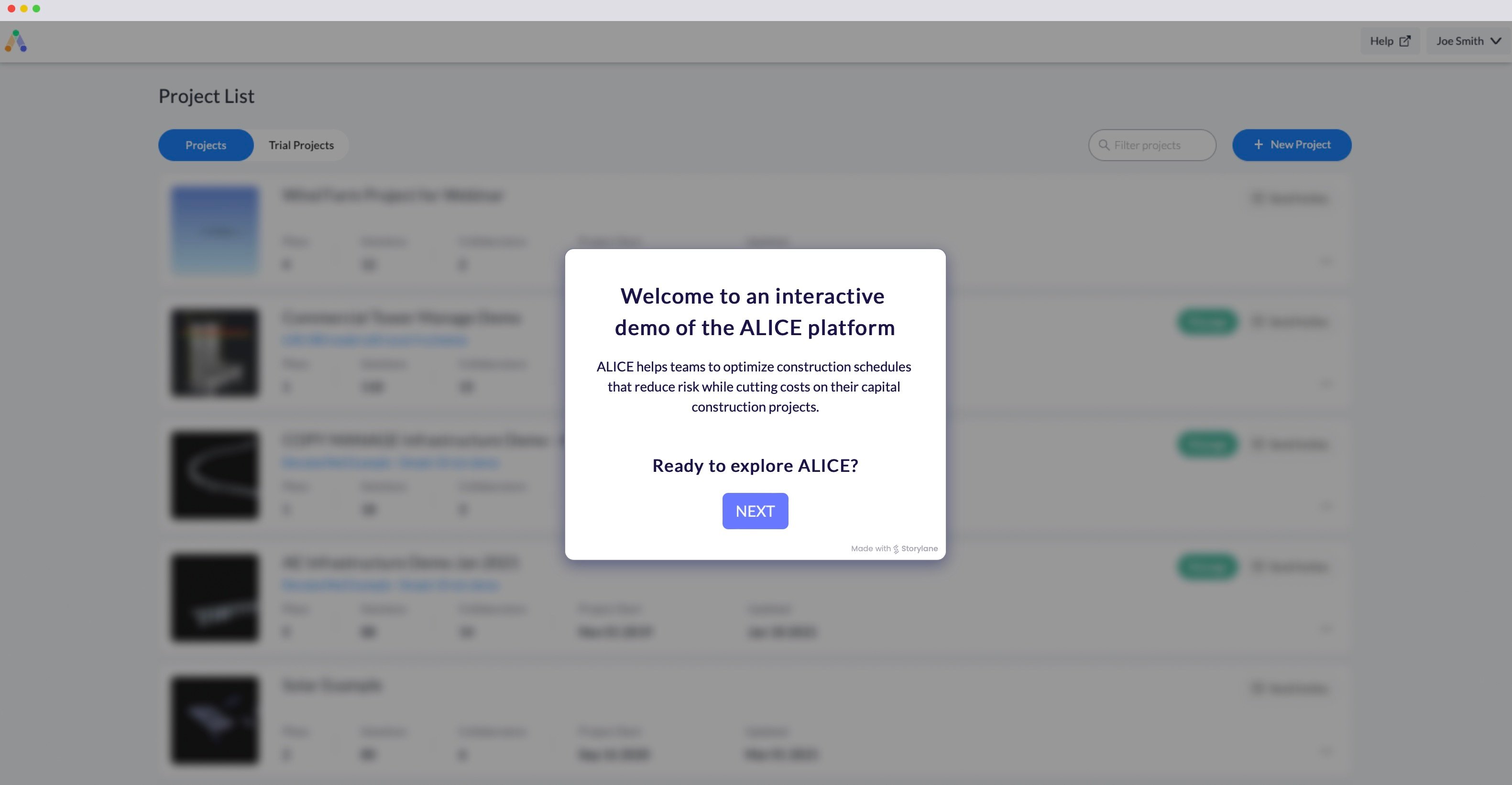

Interactive product tour of the ALICE platform

Take this interactive product tour of ALICE to explore the platform's different features.

Oil & Gas Construction Project Scheduling Software

Frequently asked questions

-

The time it takes to construct oil pipelines varies mainly based on the size. Small pipelines could take up to a year to build and large pipelines could take 4+ years. Pipeline projects could have their timeline increased by additional factors such as the terrain, engineering challenges, and regulations where the pipeline is going to be built.

-

The first step in pipeline construction is planning what areas it will be built in. Next would be to acquire the right permits to build so the land can be cleared and trenches can be dug. Once trenches are dug, pipes need to be welded and tested. After the pipes clear testing they can be laid and the excavated land can be filled back in.

-

Depending on the size of the refinery it can take anywhere from 3 to 5 years. Location is another large factor that can add time to the construction process due to things like local climate, regulations, and permits required to start building. Once the construction project has been approved considerations should still be made for testing or engineering challenges.

-

Upstream oil and gas processes would include searching for resource reserves and then drilling and extracting them. Downstream oil and gas processes would be refining, marketing, distributing, and selling those acquired resources into products we commonly use like gasoline, jet fuel, plastic products, and petrochemicals.

-

A refinery converts oil into products like fuel, heating oil, waxes, and lubricants with distillation and other processes. A petrochemical plant works downstream from the refinery by converting its products and natural gas into commonly used chemical products, pharmaceuticals, and plastics from processes like polymerization.