FOR OWNERS AND CONTRACTORS

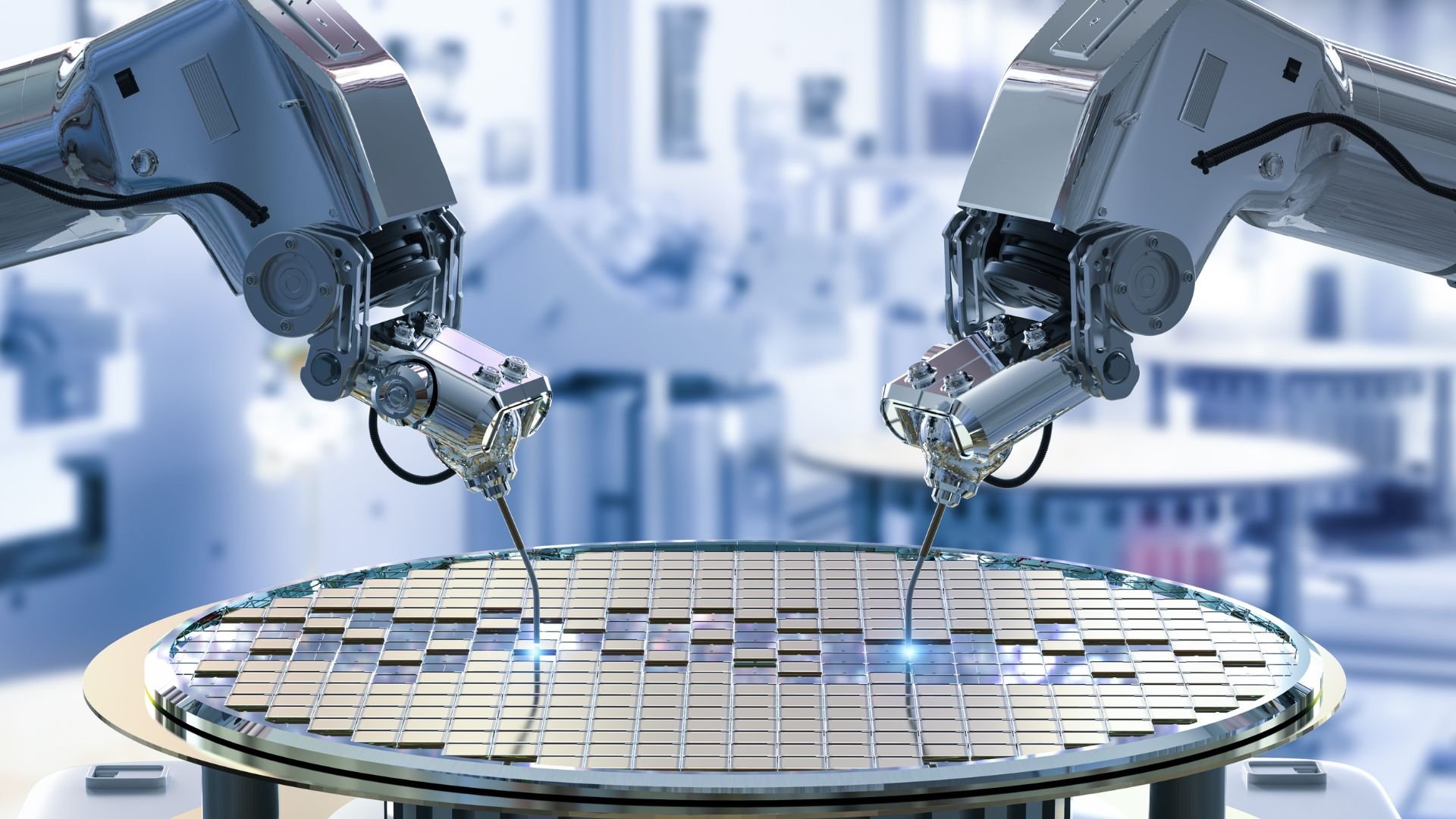

Build fabs faster with generative construction technology

Reduce risk, delays and cost overruns by optimizing the preconstruction planning and construction of your cutting-edge semiconductor fab facility with ALICE.

Accelerate your fab plant's preconstruction planning + construction with ALICE

When a fab is running at maximum capacity, it is producing millions of dollars worth of chips per day. As a result, each day saved on the construction schedule by a contractor holds immense value for the project owner.

Explore numerous ways to build before you break ground

Use ALICE to explore and simulate a variety of construction options such as simulating options to get select production lines operating before the entire facility is built and optioneer major equipment installation methods.

Cut your fab build's speed-to-market with AI

Optioneer execution strategies in ALICE to learn the cost and time impact of different scenarios, plan ahead for supply chain constraints or cleanroom construction strategies, and identify opportunities to optimize the critical path.

Reduce risk through optioneering

Create an optimal project schedule and resource allocation with ALICE to optimize cost-effective project delivery. ALICE further assists in mitigating delays by automatically generating corrective schedules.

WHITEPAPER

Building a cutting-edge semiconductor faster with generative construction technology

This whitepaper explores the use of generative construction technology in the design, planning and construction of cutting-edge semiconductor fabrication plants. By leveraging generative construction technology, the semiconductor industry can revolutionize the way fabrication plants are planned and built.

"Through optioneering with ALICE, we brought our new manufacturing facility to market three weeks early. The product paid for itself many times over with just a single project."

Semiconductor Fabs Construction Management Software

More resources from ALICE

Overview: ALICE for fab construction

Read how you can accelerate and optimize your semiconductor fab construction project with ALICE.

Webinar: Generative AI meets construction

In this webinar, we answer the million-dollar question: can generative AI be applied to construction workflows?

Interactive product tour of the ALICE platform

Take this interactive product tour of ALICE to explore the platform's different features.

ALICE PRICING

Tell us about your project needs and we’ll follow up with a consultation call to discuss how ALICE can drive results and share tailored pricing →

What type of company do you work for?

What is the size of your project?

What are your top priorities?

Which of the following best describes your business model?

What are your top priorities?

What is the construction value of your average project?

We need a bit more information to prepare your custom quote

Almost done! How should we reach out to you?

Tell us more about yourself.

Thanks!

We’ll review the information you submitted and be in touch shortly. In the meantime, check out some of these links if you want to learn more about us.

ALICE works with the world's leading contractors to solve their most pressing construction challenges with semiconductor fabs construction software.

Optimize every construction phase with ALICE

ALICE gives you new planning and construction super powers

Semiconductor Fabs Construction Project Scheduling Software

Frequently asked questions

-

In order to build a semiconductor factory you will first need to have the permits and funding in place. Then creating the design of the facility with utilities and cleanrooms in the layout would be next to have better control over the environment for semiconductor fabrication. And the final steps would be installing the tools needed for fabrication along with testing and packaging areas.

-

Depending on the size of the semiconductor factory it can take anywhere from 1 to 4 years. Additional factors that can increase the project timeline would be acquiring the factory equipment, building it in accordance with regulations, or issues with stakeholders and project management.