FOR OWNERS AND CONTRACTORS

Optimize tunnel construction with generative construction technology

Tunneling owners and contractors use ALICE to create an optimal construction sequence and resource allocation plan to maximize productivity for timely and cost-effective project delivery.

ALICE is purpose-built for owners and heavy civil contractors building tunnels to help maximize efficiency, minimize costs, and improve project duration

Optioneer before you break ground

Use ALICE to explore and simulate a variety of construction options such as factoring soil removal, simulating the multiple tunnel boring machines (TBM) machines to determine the optimal number of TBMs and sequence of activities and more.

Optimize productivity + grow margins

Optioneer execution strategies in ALICE to identify the cost and time impact of your decisions, for example:

What if we resequence the mucking crew?

How can we enable an earlier construction start on the second access point?

Use ALICE as a generative risk mitigation tool

Model different risk scenarios in ALICE and gain insight into how they could potentially affect the project timeline. ALICE automatically generates risk-mitigated schedules to help you develop robust contingency plans.

CASE STUDY

SCS JV leverages ALICE to drive £2M savings on the London tunnels of the UK's High Speed 2 railway

CUSTOMER: Skanska Costain and STRABAG JV

Three major European general contractors – Skanska, Costain, and STRABAG – formed a joint venture, SCS JV, to optimize the construction of the London tunnels of HS2, a national high-speed railway linking London, Birmingham, and the north of the country.

The SCS JV wanted to use ALICE to find efficient sequencing options to enable an earlier construction start. Through “what-if” analysis with ALICE, the SCS JV team was able to identify a number of ways to resequence and improve the build time for the pre-shaft sinking activities.

“The savings of both time and money that we’ve identified with this initial work on SCS East has been significant, and we’re now looking forward to expanding our use of ALICE to other portions of the project.”

Tunnels Construction Management Software

More resources from ALICE

ALICE for linear projects

Explore how ALICE resolves linear construction challenges such as access point constraints, easements, logic and sequencing, etc.

Risk Management with ALICE

ALICE models specific risk events using generative construction technology to determine the most effective recovery scenarios from a wide range of variables.

Mega Surprises of Megaprojects

Discover surprising insights about the challenges and complexities of megaproject construction and how ALICE can improve planning and execution.

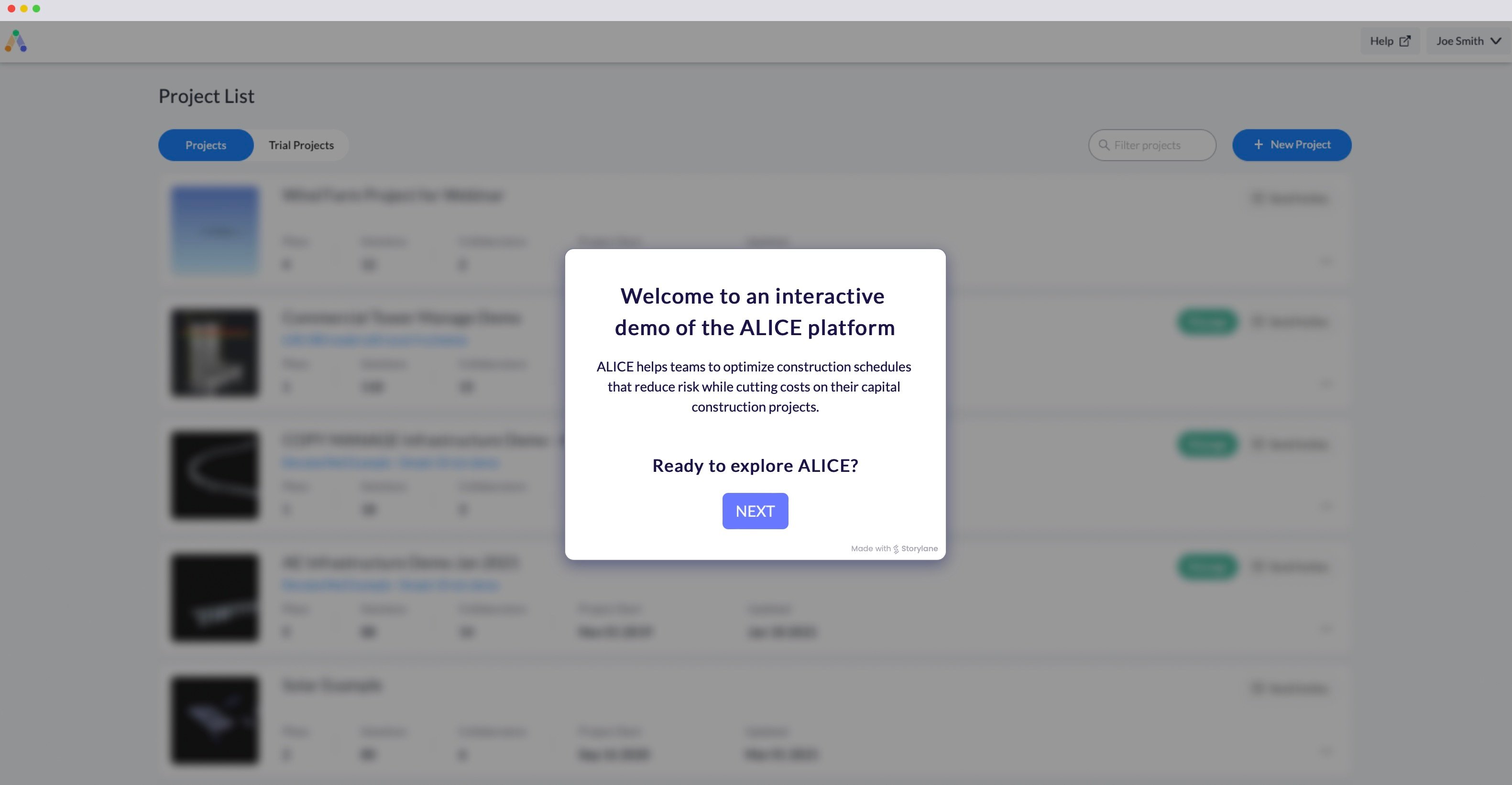

Interactive product tour of the ALICE platform

Take this interactive product tour of ALICE to explore the platform's different features.

ALICE PRICING

Start here to get your custom quote now

What type of company do you work for?

What is the size of your project?

What are your top priorities?

Which of the following best describes your business model?

What are your top priorities?

What is the construction value of your average project?

We need a bit more information to prepare your custom quote

Almost done! How should we reach out to you?

Tell us more about yourself.

Thanks!

We’ll review the information you submitted and be in touch shortly. In the meantime, check out some of these links if you want to learn more about us.

Optimize every phase with ALICE

ALICE gives you new planning and construction super powers

Tunnels Construction Project Scheduling Software

Frequently asked questions

-

Building a tunnel is an in-depth process requiring construction company owners and general contractors to assess several aspects of the project and its surroundings. For instance, you’ll need to evaluate the type of ground that the tunnel is being built on (soft ground, hard rock, soft rock, subaqueous) before construction begins.

That being said, the procedures involved in constructing a tunnel are relatively consistent. These processes include the following:

- Investigation

- Excavation

- Material transportation

- Ground support

- Environmental control

-

The average person is unaware of how many intricate components are required to build a tunnel, regardless of its location. Although the exact components may vary based on your project, standard tunnels require the following components:

- Soil

- Segment lining with support measures

- Tunnel boring machine (TBM) with hydraulic jacks

- Grouting

If you plan on working on an urban tunnel (in a city or large town), you’ll also need to keep the current infrastructure in mind.

-

Construction company owners need to address a handful of challenges before and during the tunnel construction process. One of the main challenges is geological variability, which refers to the variance of the consistency of the soil/rock on which the tunnel is being constructed. For instance, if the soil/rock is softer than expected, your team will need to adjust their processes.

Groundwater is another common issue construction company owners face during tunnel construction. Project stakeholders need to clearly identify all sources of groundwater (prior to construction) to prevent groundwater from potentially hindering operations.

-

Constructing a tunnel in an urban area is quite challenging for even the best construction company owners. This is due to the fact that there are several challenges and hurdles that need to be addressed before and during the construction process. Some of the most common challenges of building a tunnel in an urban area include:

- Shallow cover

- Difficult soil conditions

- Groundwater infiltration

- Proximity to sensitive structures (ex. historic buildings)